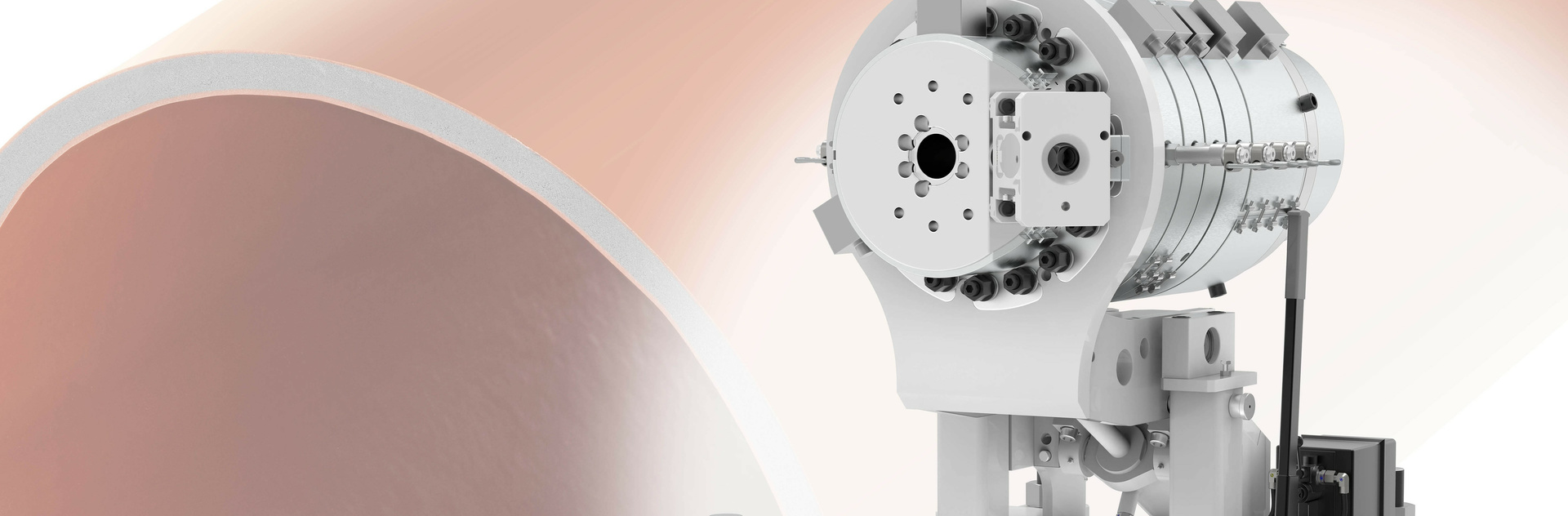

Co-rotating Twin Screw Extruder (ZE) Petrochemical

Product information

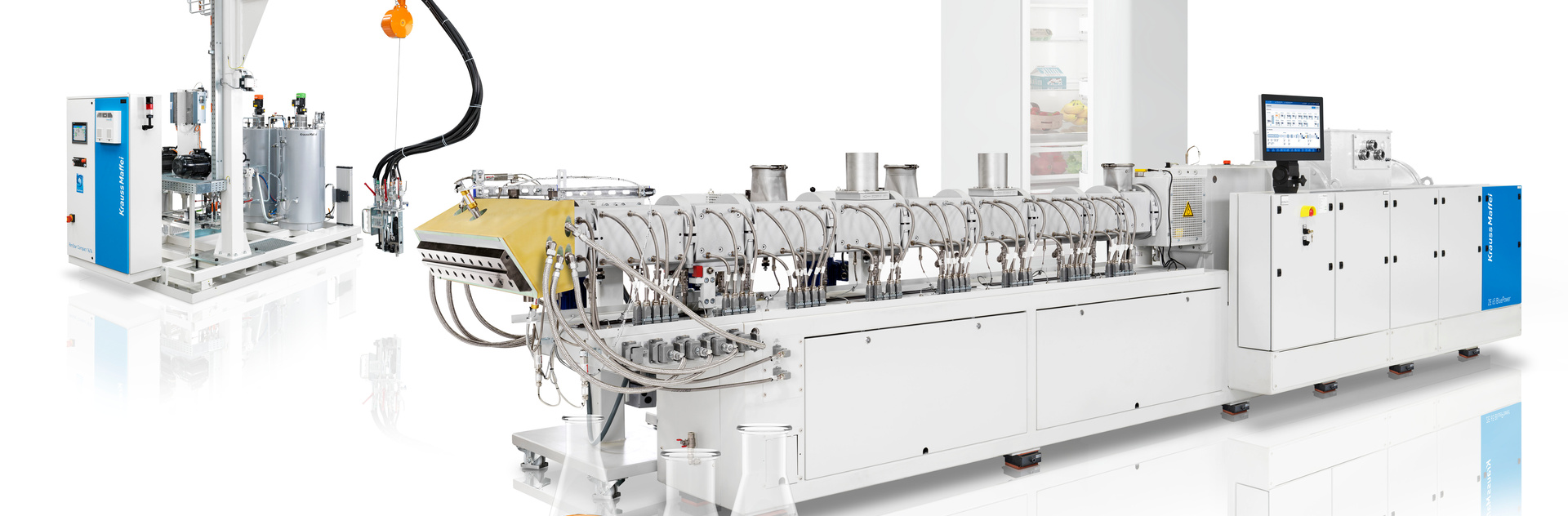

Our ZE PC series offers the ideal solution for discharging powder and melt directly from polymerization. With outstanding devolatilization performance, they ensure the efficient removal of volatile components — delivering maximum polymer purity and quality. Rely on superior efficiency, process reliability, and exceptional results.

Performance data

Sizes: 260, 300, 330, 365 and 400 mm

Diameter ratio: DA/DI of 1.65

Throughput from 25 t/h up to 130 t/h

Why our product stands out

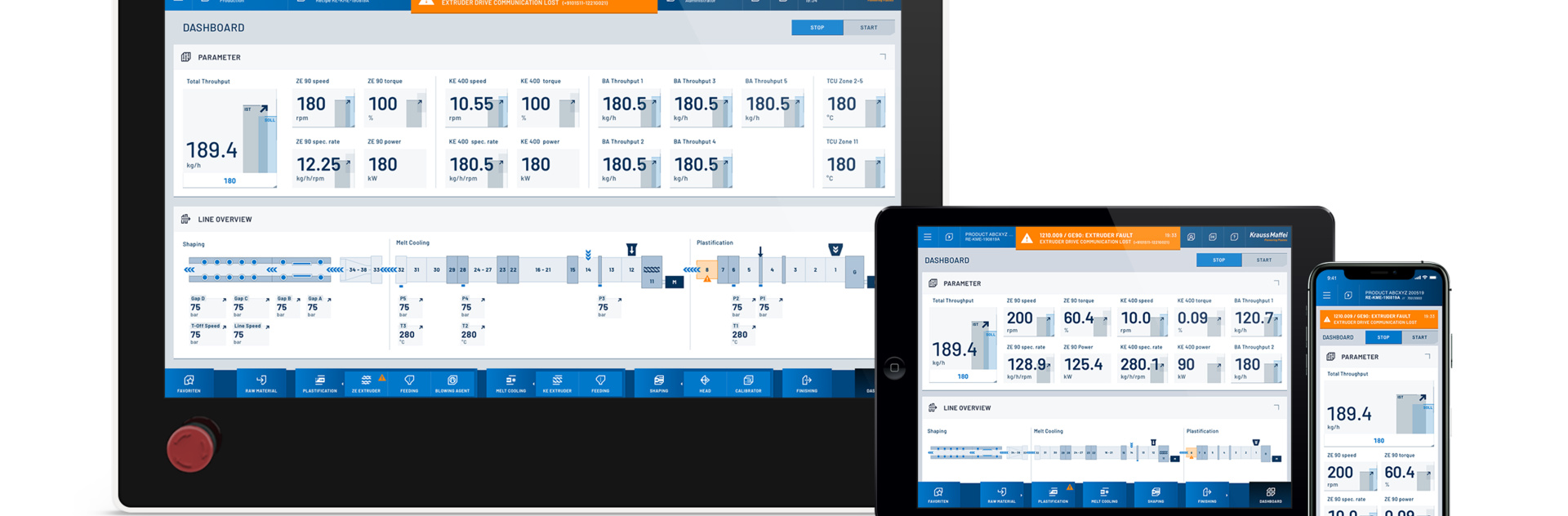

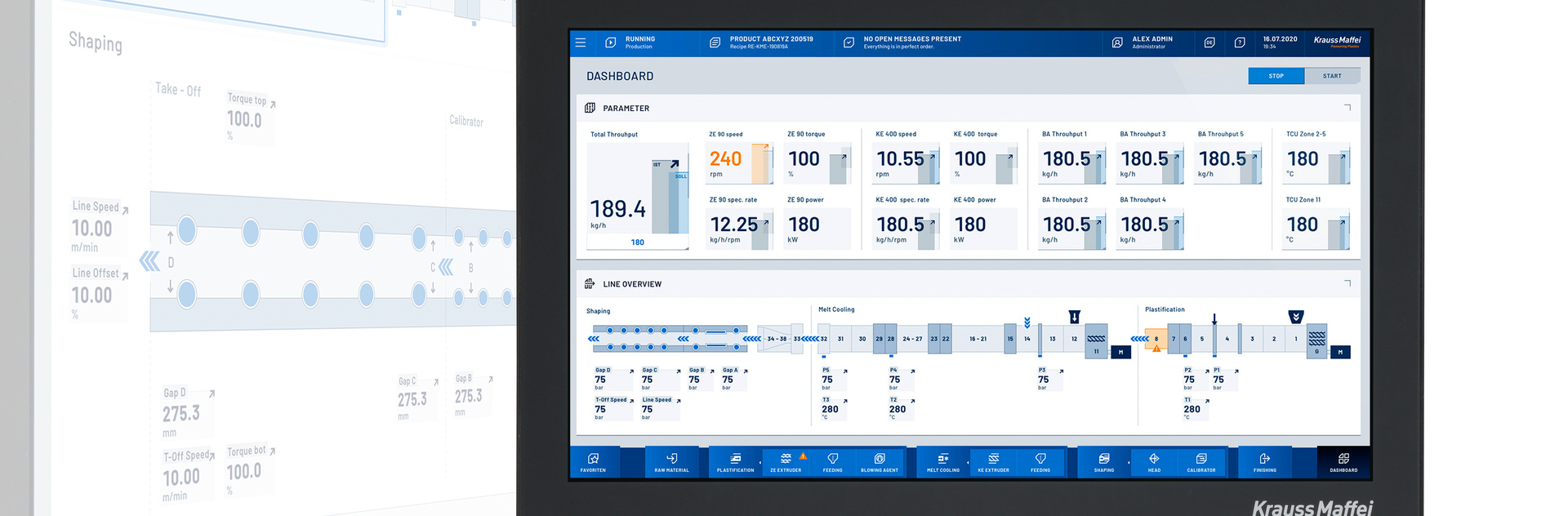

- Maximum modularity thanks to 3D housing and base frame modules

- Well-known/established suppliers in the market and good accessibility

- modular screw

- Customer products: Discharge extruder: PP, HDPE and MDPE

- High wear protection and low energy consumption

Use cases

Industries

Circular Economy & Recycling

Chemical

Medical technology

Consumer Goods

Electrical & Electronics

Lennart Eberlein

Teamlead Expert Sales Compounding & Recycling