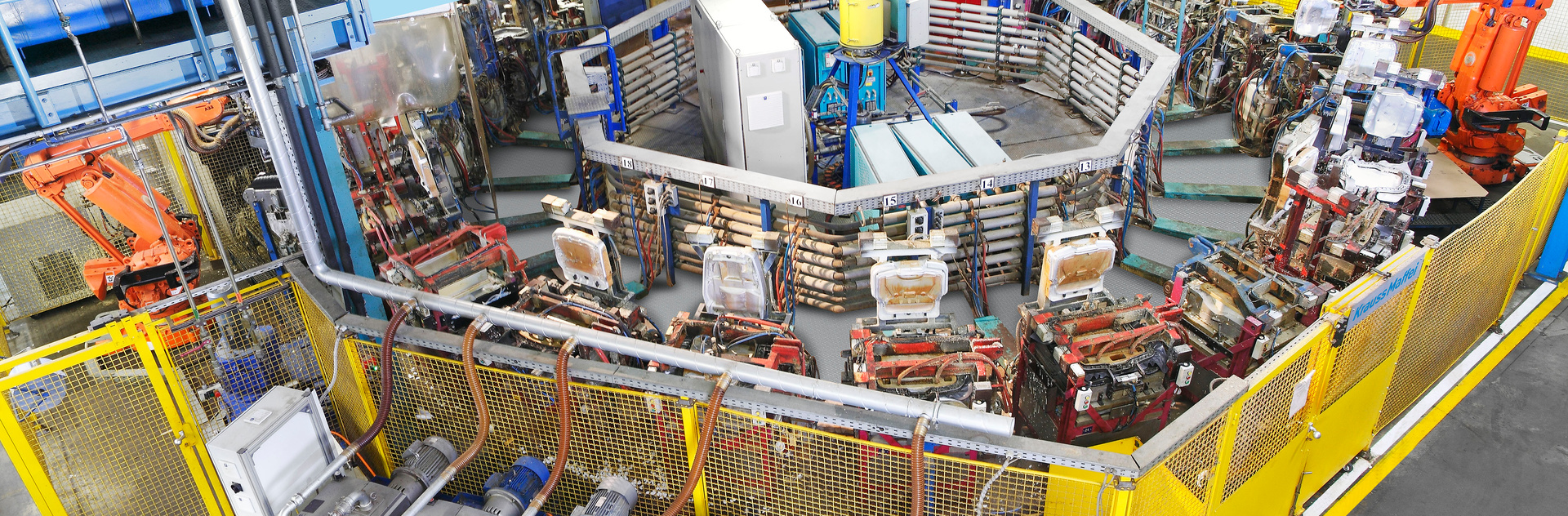

Transfer mixing heads

Up to 8 components

Product information

Whether you require maximum precision, maximum flexibility, or fast recipe changes, our Precision, Deflection, and CN mixing heads offer tailor-made solutions for a wide range of PUR applications. Each mixing head impresses with its specific strengths—together, they stand for reliable processes, excellent mixing quality, and innovative technology through countercurrent injection.

Use cases

Industries

Together they stand for reliable processes, excellent mixing quality, and innovative technology

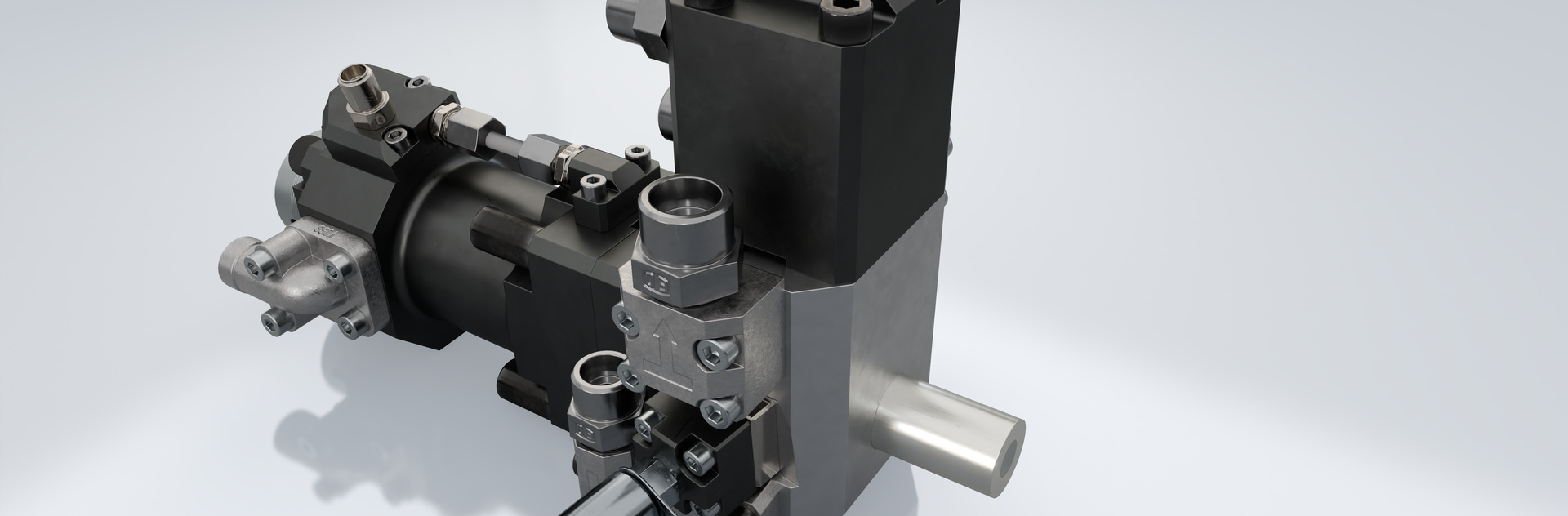

With the precision mixing head, we are now introducing a completely redesigned concept. Smaller, lighter, more powerful, and particularly easy to service, the precision mixing head sets new standards in its class.

Key features of the precision mixing head

- Quick replacement of wear parts

- 30% larger process window

- State-of-the-art simulation methods

Precision and versatility for demanding PUR applications – KraussMaffei deflection mixing heads stand for maximum mixing quality, reliable process control, and flexible integration into a wide range of PUR processes. Thanks to their sophisticated technology and robust design, they are the first choice for applications with high demands on quality and repeat accuracy.

Key features of the L-Shape mixing head

- High-pressure counterflow injection principle for excellent homogenization

- Special arrangement of the injection angles for optimum mixing quality

- 90° outlet pipe to stabilize the reaction mixture

- Cartridge technology for quick and maintenance-friendly nozzle replacement

- Optionally positionable cleaning piston to influence mixing quality and discharge behavior

- Versatile – even for complex multi-component systems

Fast and precise – mixing of up to six raw material components using the high-pressure counterflow injection principle. The shorter the intervals between shots, the higher the demands on the mixing head control.

Core features of the CN mixing head

- Variation in discharge quantities and recipes from shot to shot

- Very short shot sequences of 0.8 seconds with cleaning stroke and complete recipe adjustment

- Variable cleaning piston positioning

- Adjustment of the discharge capacity via Vario nozzle in the range 1:5

- Integrated bypass system for efficient component selection

- Optimized nozzle geometry for improved foam quality

A very special mixing head with two completely independent component circuits. With two different systems for one mould.

Key features of the Duplex mixing head

- Process-safe solution for applications with 2 different foam systems

- Simple system technology

- Easy to handle

- Each component circuit has its own spool

- Spool can be controlled individually