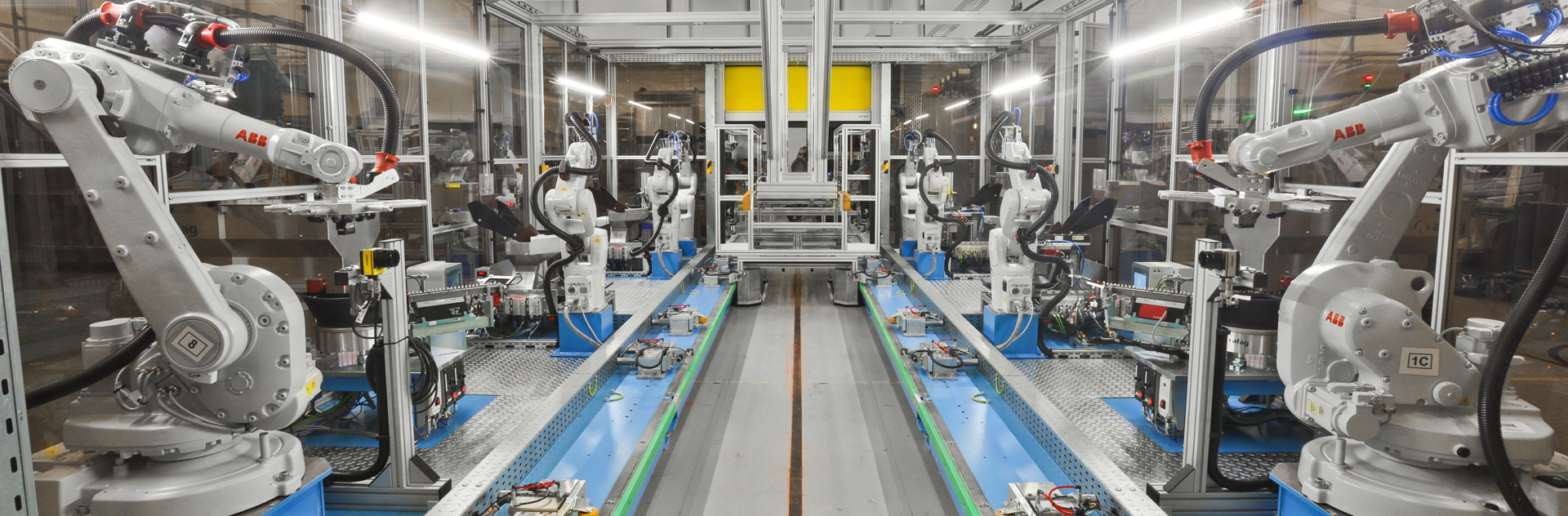

RimStar IQ

Dosing machine ready for digitalization and autonomous operation

Product information

RimStar IQ dosing machine with new digital features: the machine and process are now even easier to control, even for less experienced users. The vision for the future is autonomous operation.

- New features to prepare for digitalisation

- The path to autonomous operation

- Machine and process even easier to control, even for less experienced users

- New Human Machine Interface (HMI)

Advantages that make the difference.

dataXplorer

digital analysis tools integrated

Process data

record and analyse

Automatic adjustment

to wear and external influences

Use cases

Industries

Automotive