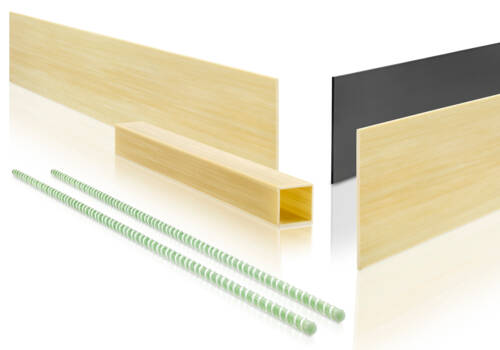

The Long Fiber Injection (LFI) process enables the cost-efficient production of large, fiber-reinforced components with high stability and excellent surface quality. In this process, continuous fibers are cut inline, separated with air support, and immediately wetted with a polyurethane matrix. The combination of high design flexibility, variable fiber lengths, and moderate tooling costs makes LFI particularly attractive for applications in the automotive, construction, and commercial vehicle sectors.

Key Features – LFI

- Long fibers (20–100 mm) are chopped inline and mixed with PUR

- Open mold process: spray or pour application guided by robots

- Fast curing: cycle times of just a few minutes

- High stiffness at low weight