Door foaming systems

Our stationary systems, drum or circulation systems

Product information

Our expertise and technologies in the White Appliance and Insulation sector are your advantage. In order to ensure customer satisfaction, we stand for proven engineering capability and dedicated customer support.

Use cases

Industries

Cooling Technology & Insulation

Infrastructure & Construction

Innovative, efficient solutions for White Appliance and Insulation

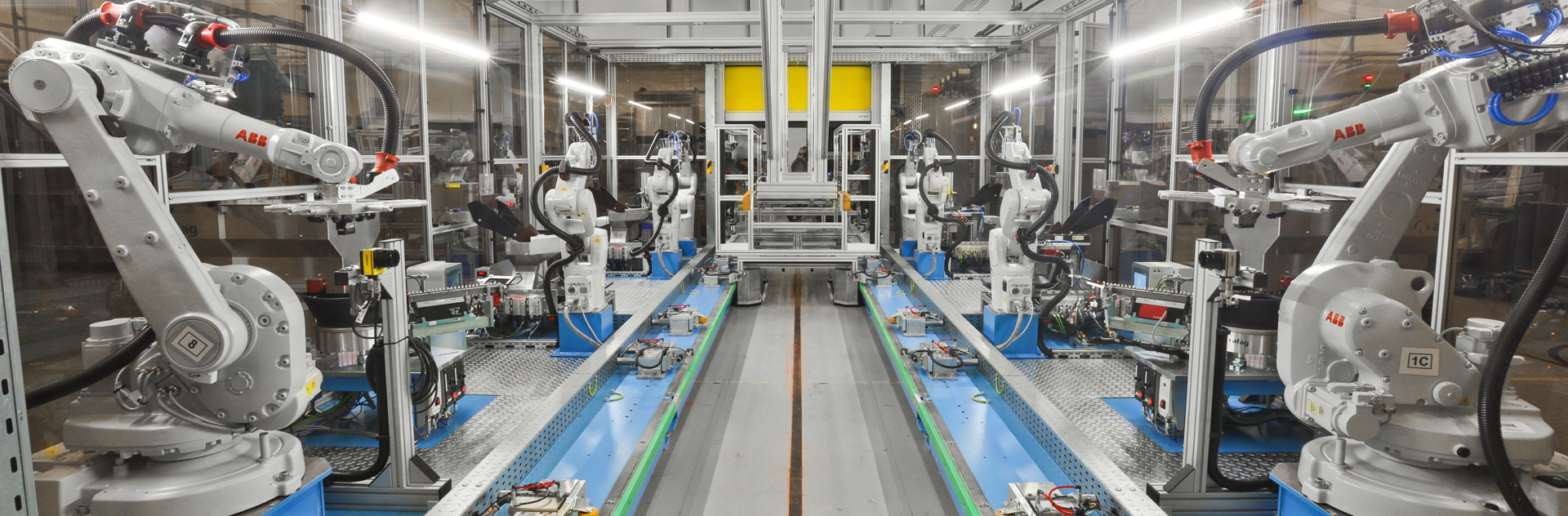

Stationary equipment

- Automated loading and unloading for efficient processes

- Flexible adaptation to different door models

- Precise fixture movements for high repeat accuracy

- Temperature control for optimum foam quality

- Central control & remote maintenance for easy operation and service

- Compatible with all propellants, including pentane

Drum systems

- Compact solution for high quantities

- Compact, stable drum design with 4–8 fixtures

- Fast rotation via gearbox and motor

- Single or double mixing head carrier for multiple foaming

- Open or closed mold foaming possible

- High repeat accuracy and energy efficiency

Circulation systems

Automation Meets Ergonomics - The fully automatic Door Foaming Flex Conveyor Line offers maximum flexibility, high output, and uncompromising quality for refrigerator door production and other foamed components. It also offers automatic tool change during the cycle time and a tool magazine with and without oven function.

- Stop&Go concept for flexible, mixed production without time loss

- High automation level with intelligent mold and process integration

- Compatible with all door types and blowing agents – including pentane