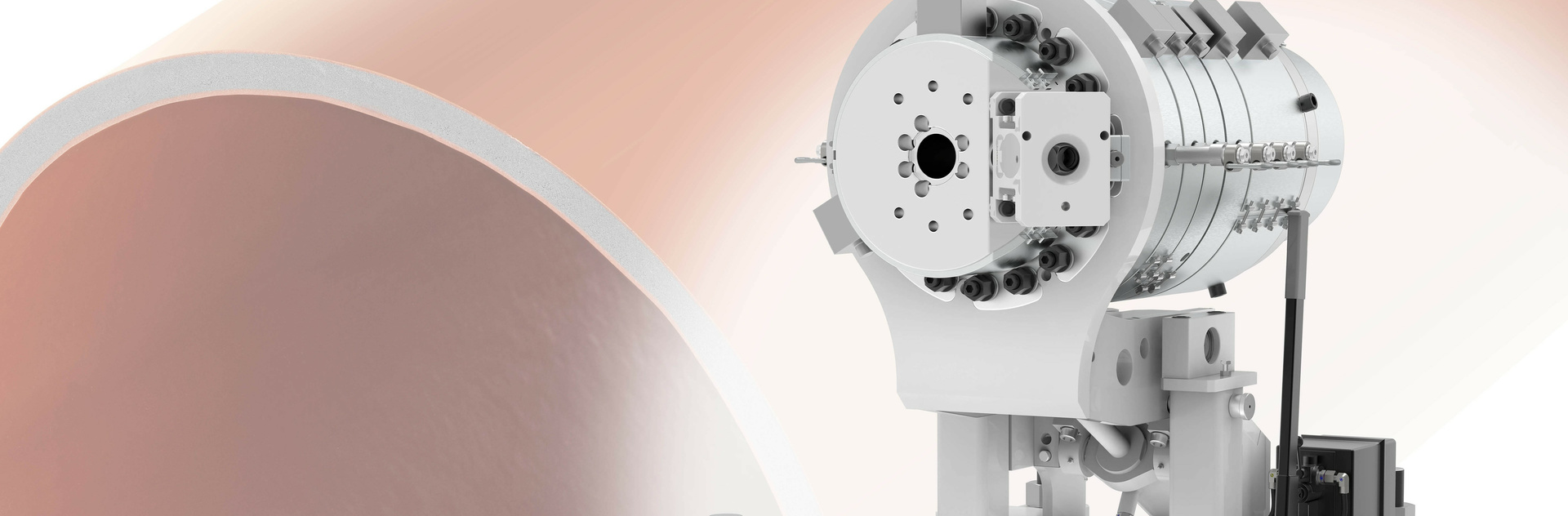

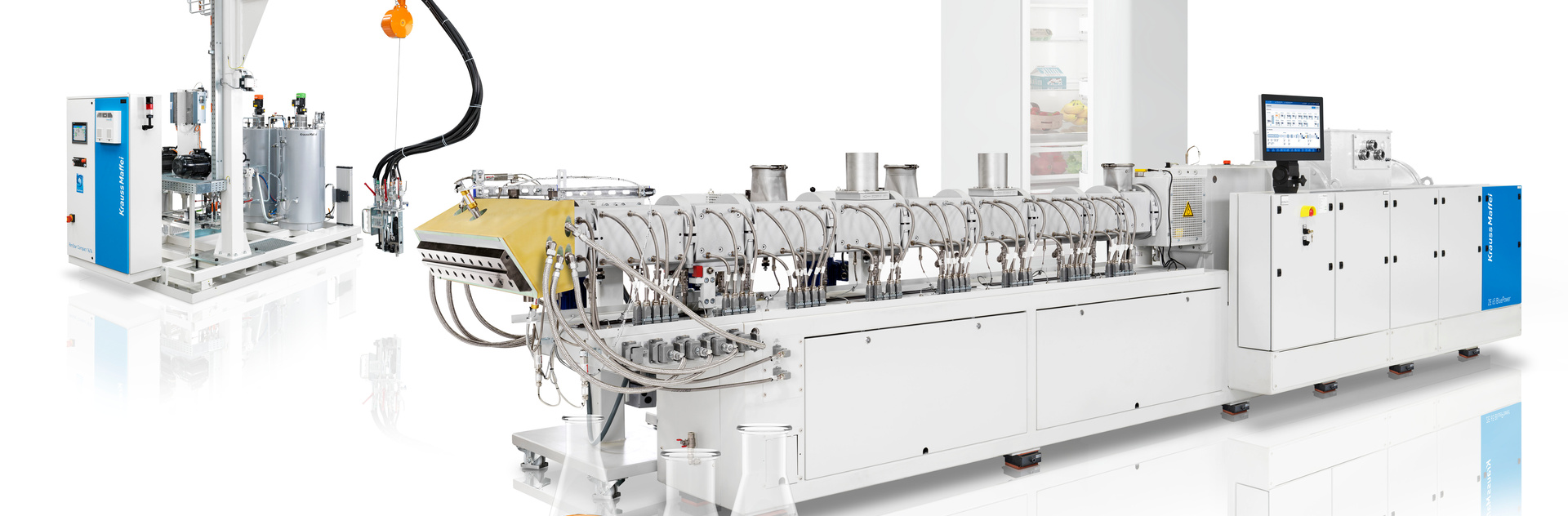

Roller Head Extrusion Line (RH)

Product information

KraussMaffei Extrusion’s Roller Head technology offers the perfect combination of precision and cost-efficiency: achieving extremely tight tolerances in the production of inner liners, plies, edge covers, or squeegee strips. The two-roll calender, working in conjunction with the extruder and the wide-slit die head, precisely shapes the rubber sheets for subsequent processing steps. Bend-optimized rolls and a hydraulic gap adjustment ensure an exact thickness.

Performance data

For 60 mm – 250 mm Extruder

Product width 0,6 m - 3,8 m

Product thickness of 0,3 - 25 mm

Why our product stands out

- Movable extruder for maintenance and conversion work

- Hydraulic opening and closing of the wide-slit die head for quick cleaning

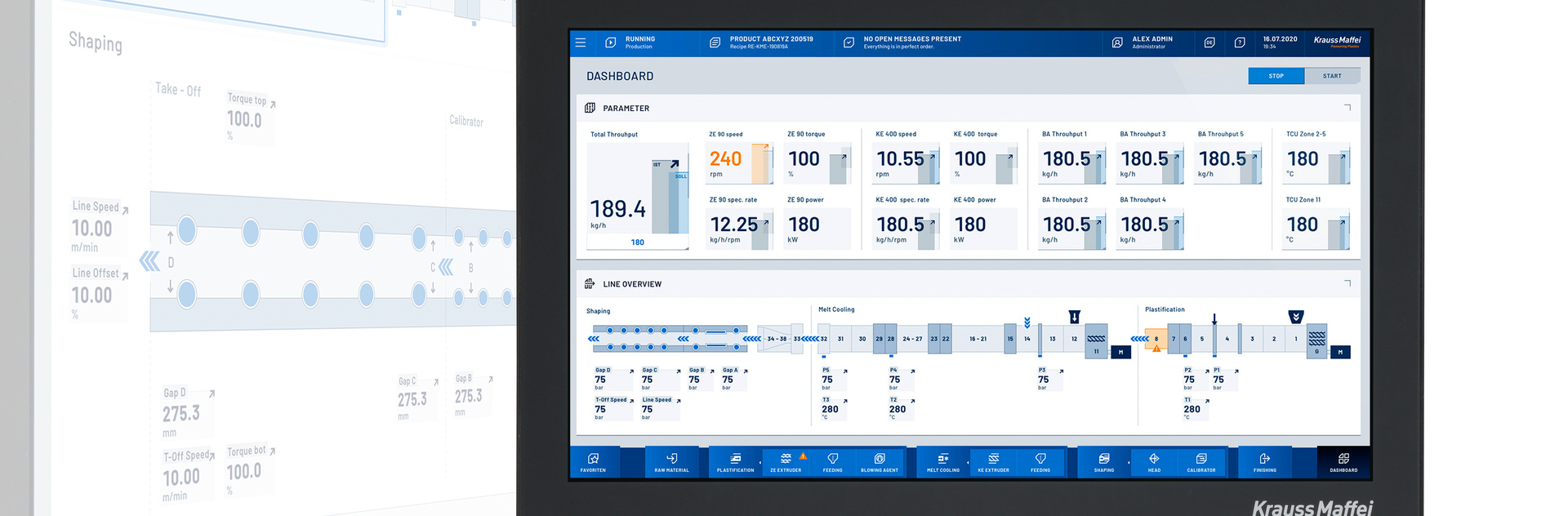

- Extremely tight tolerances across the entire sheet width and optimal compound homogeneity

- Minimal downtime thanks to simple and quick roll replacement

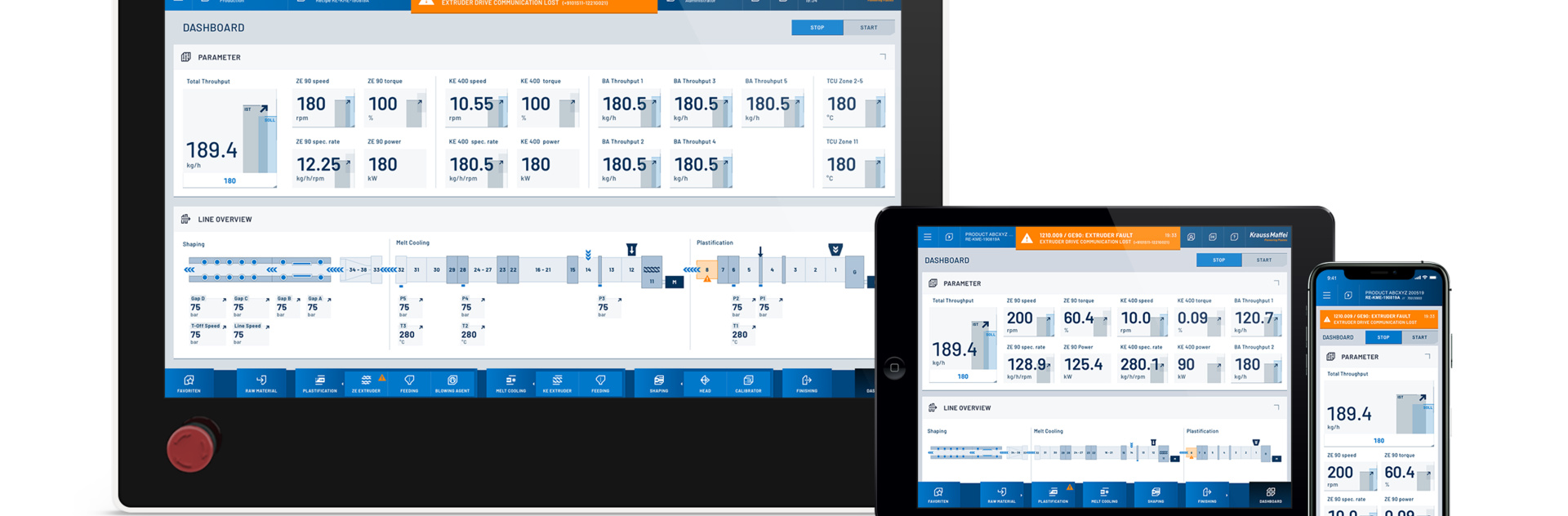

- Easy operation, low-maintenance design and high safety standards

Use cases

Industries

Automotive

Public Transportation & Utility

Consumer Goods

Patrick Michalke

Teamlead Expert Sales Tire & Rubber