Single-screw Extruder (KME)

Features

Product information

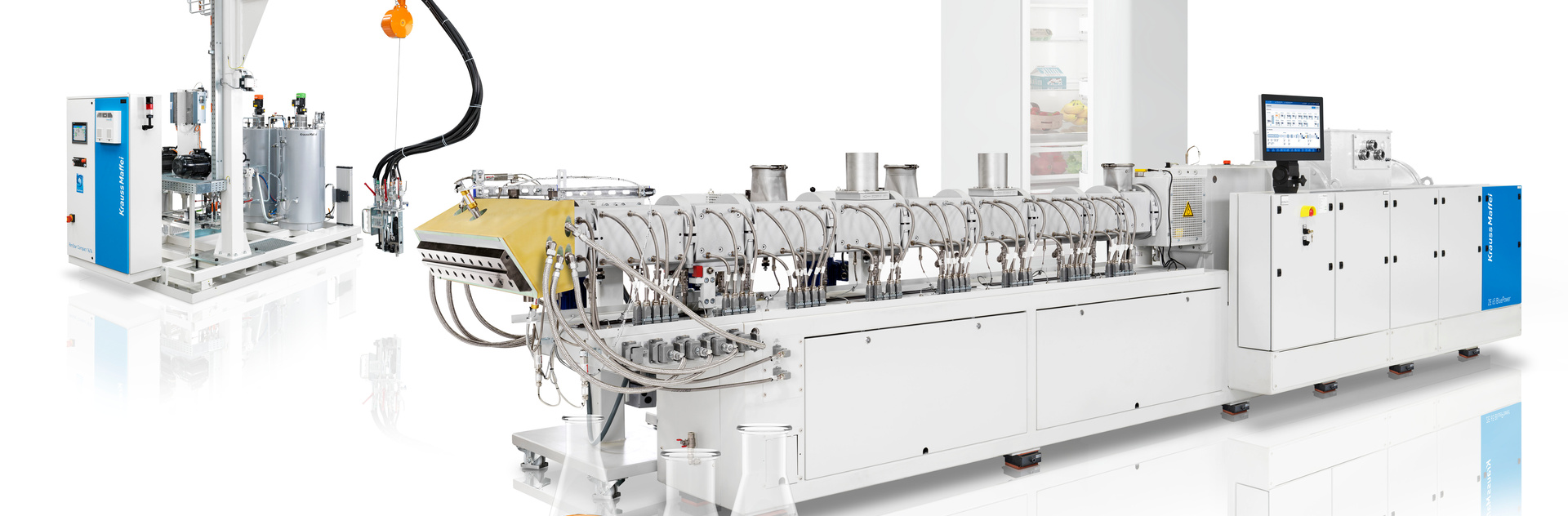

The proven 36D single-screw series combines highest product quality with first-class efficiency. This series is supplemented by the 30D single-screw extruder series, which is used primarily for low output rates as a co-extruder. The two series with processing units of different lengths are ideally equipped to meet market requirements for economical production.

Performance data

Process length:36D, 30D

Throughput: up to 2000 kg/h

Internal Pipe cooling (IPC) Technology

Why our product stands out

- Customized solutions: Tailor-made machine and plant configurations for all pipe extrusion tasks, including customer-specific special solutions

- Efficient process technology: High output rates, excellent melt homogeneity, and gentle melt processing at low melt temperatures

- Durability and safety: Optimized pressure profile, low wear rates, and high process reliability

- Resource-efficient and low-maintenance: Low cooling water consumption and a proven low-maintenance U-design drive concept

- Innovative technologies: IPC internal pipe cooling for higher productivity and reduced screw and barrel wear

Use cases

Industries

Infrastructure & Construction

Automotive

Klaus-Dieter Lorius

Teamlead Expert Sales Pipe & Profile